LOGOS LTD s.r.o. is a Slovak technology and manufacturing company focused on the recovery of plastic waste through advanced chemical recycling as a direct response to the direction of the EU waste management in the area of recovery of mixed plastic waste and its use within the raw material base.

Preventing plastic waste from polluting the environment through advanced recycling technology.

Over 50 employees committed to transforming waste into valuable resources.

Converting waste into fuel and secondary materials for chemical and oil & gas industries.

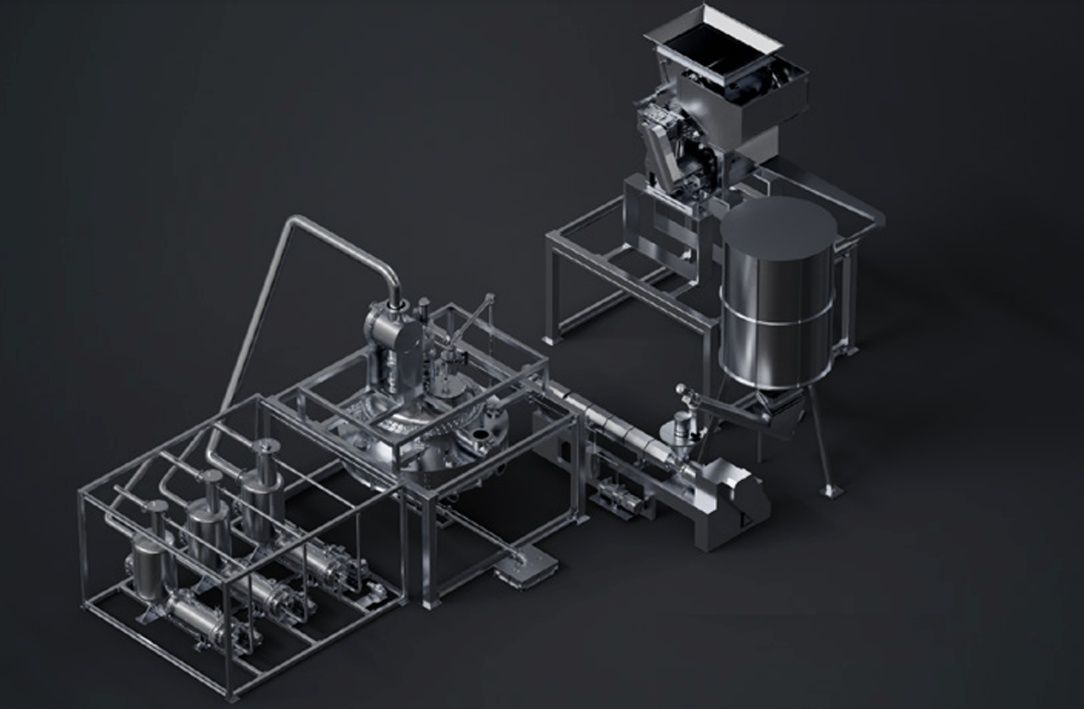

We transform plastic waste that cannot be recycled into valuable chemical feedstocks, supporting a circular economy.

Our chemical recycling process produces secondary fuels as a substitute for fossil fuels while reducing emissions.

Our low-emission, zero-toxic process ensures environmental safety and eco-friendliness, supporting a greener future.